SCORPION HKII-7050-330KV Brushless Motor

The Scorpion

HKII-7050-330KV motor provides 10KW of maximum continuous power and with maximum

of 200Amp current,

can apply on large application such as e-bike, e-boat or

large UAV.

Specifications:

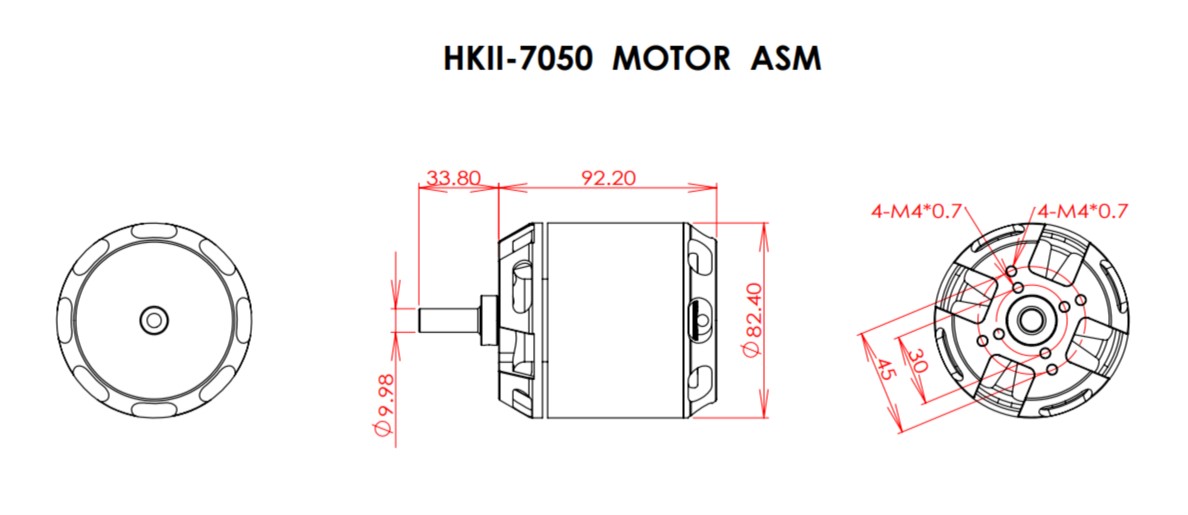

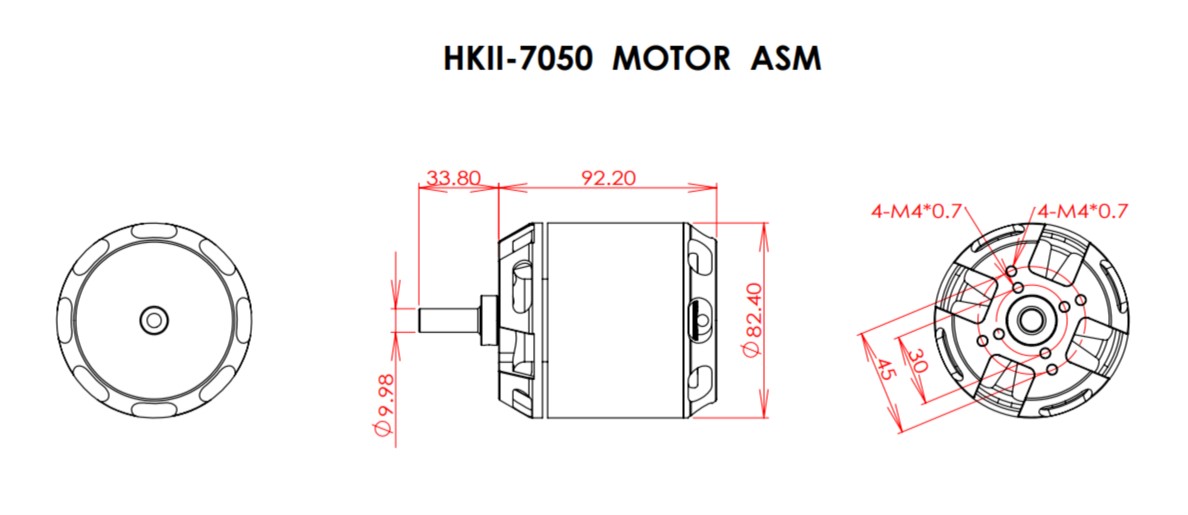

Stator Diameter: 70

mm (2.76 in)

Stator Thickness: 50

mm (1.97 in)

No. of Stator Arms:

12

Magnet Poles: 10

Motor Wind : 2T/3T

Turn Delta

Motor Wire: 2 -

Strand 1.8mm

Motor Kv: 330KV RPM

/ Volt

No-Load Current

(IO): 3.6 Amps @ 10v

Motor Resistance

(RM): 0.005 Ohms

Max Continuous

Current: 200 Amps

Max Continuous

Power: 10000 Watts

Weight: 1915 Grams

Outside Diameter:

82.4 mm (3.24 in)

Shaft Diameter: 9.98

mm

Body Length: 92.2 mm

Overall Shaft

Length: 126.0 mm

Max Voltage: 50V

Peak Current: 300A

(5 seconds)

Peak Power : 15000

Watts (5 seconds)

Included in the Box:

1 x Scorpion

HKII-7050-330KV Motor

4 x M4 Screws

Weight including

packaging: 2400g

From 18th December 2011 when Scorpion HK-7050-340kv was released, a lot of feedback by developers in all facets of the large electric-power hobby has been received that it has well established itself as the Gold Standard of the power for e-bike, e-surfboard, e-boat, water jack pack and large UAV. The HK-7050-340kv motor has proven itself to be extremely successful in large e-hobby community, and has become the most powerful motor used world-wide.

And now we are pleased to announce the release of the new generation HKII-7050-330kv motor. With the single strand winding technique on this size of motor, it has the best efficiency and power conversion, with an entirely new EM field design, while improving the compatibility with various speed controllers available on the market. This new design motor will deliver even more power to your e-hobby equipment, with increased efficiency!

The Scorpion Brushless Motors are built from the best materials available, and are designed to provide both quality and performance at an affordable price. Scorpion starts with high quality aluminum alloy parts that are produced on the latest CNC milling machines. These parts are then gold anodized to provide a beautiful, long-lasting finish. The stators are made with 0.2 mm laminations to give maximum efficiency, and minimum Eddy current losses. The stators are epoxy coated to prevent shorts, and are wound with wire that is rated at 180 degrees C (356 F). The magnets used in Scorpion Motors are custom manufactured to be able to withstand high temperatures, making a motor that is virtually impossible to burn up in normal use.

Scorpion Motors are built to last, and are backed with a 2-Year warranty against defects in materials or workmanship. However, due to the high RPM of these motors, and the fact that we cannot control the installation and setup, the bearings are not covered by the 2-Year warranty, nor is any subsequent damage caused to the motor by a bearing failure. Bearings are a normal wear item, and as such, need to be maintained and changed periodically. For maximum life, make sure that a sufficient gap is left between the pinion and main gear during motor installation to avoid binding, and put a small drop of oil on each bearing every 5-6 flights. It is the responsibility of the pilot to ensure that the bearings are maintained properly.

For the best overall combination of quality, performance, and value, use Scorpion Motors in your system!